The advantages of aluminium for beverage packaging

Aluminium brings an unparalleled array of benefits to the beverage industry. Its exceptional corrosion resistance and impermeability to light and oxygen ensure that the contents remain protected for extended periods. Aluminium cans are lightweight, stackable and durable, enabling brands to optimise their packaging and distribution processes while using less material. The properties of aluminium also effectively preserve the flavor and quality of the beverage, providing a complete barrier against light and oxygen, thus maintaining the drink's freshness and taste. With a wide range of sizes, shapes, and decoration options available, aluminium cans offer an expansive printable surface area that acts as a vibrant 360-degree display for brands. These attributes make aluminium cans the preferred choice for beverage packaging among canmakers.

Elval is responsibly meeting the needs of the canmakers worldwide

Elval is dedicated to fulfilling the requirements of canmakers globally. The flat rolling aluminium facility in Oinofyta, Greece, has been recycling aluminium and producing sheets and coils for the rigid packaging market for over fifty years. Equipped with cutting-edge recycling, casting, and rolling technology, along with extensive expertise in customer technical specifications and ongoing R&D in metallurgy and surface technology, Elval delivers bespoke solutions, innovative shapes and sizes, and alternative coatings to meet diverse industry needs.

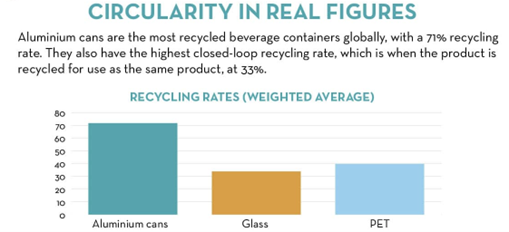

Quantifying Circularity

Aluminium cans stand out as the most sustainable packaging option due to their infinite recyclability without compromising their original quality. A study commissioned by the International Aluminium Institute (IAI) on the recycling of aluminium, glass, and PET plastic has highlighted the critical role of aluminium cans in fostering a circular economy. The findings reveal that over 70% of the material used in aluminium cans is recycled into new products, nearly double the rates for glass (34%) and plastic (40%).

Remarkably, it takes as little as 60 days for an aluminium beverage can to be recycled and back on store shelves. Following consumption, it can be collected and recycled again, embodying the concept of a reborn can. This process allows aluminium cans to be recycled indefinitely, generating significant energy savings. In fact, recycling aluminium requires approximately 95% less energy than producing it from raw materials—a reduction that leads to lower greenhouse gas emissions.

With global demand for beverage cans projected to rise from 420 billion units in 2020 to 630 billion by 2030, achieving full recycling of all cans worldwide by 2030 has the potential to yield savings of 60 million tonnes of greenhouse gas emissions annually.

Currently, over 70% of aluminium beverage cans are recycled into new products; however, this percentage does not meet the necessary contribution required to reach the 1.5-degree climate target. Elval remains committed to supporting the decarbonization of the aluminium sector and will work in partnership with customers to develop innovative solutions involving high-recycled and low-carbon aluminium, thereby advancing the aluminium industry towards full circularity